Products & Services

Our Product Range

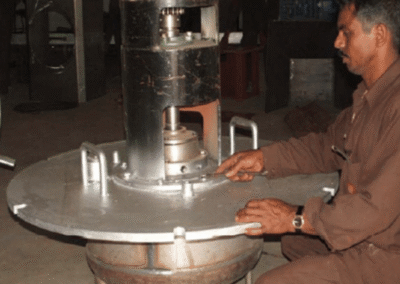

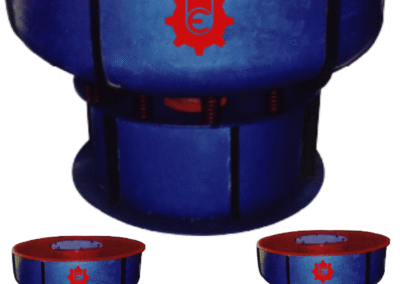

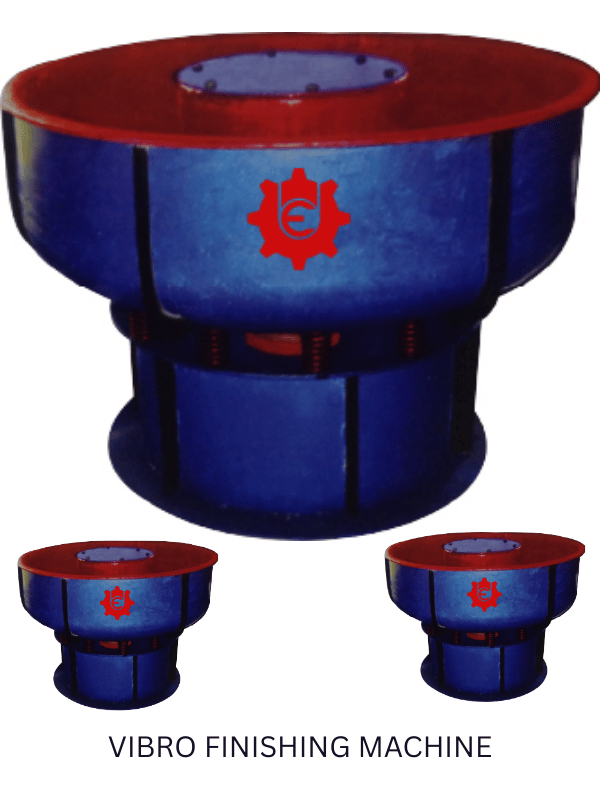

VIBRO FINISHING MACHINE

Basic Features

* Heavy duty flange/foot mounted imported vibratory motor

* Hot poured polyurethane lining with 12-15 mm average thickness with

hardness of 75-80 shore for a long life

* Solid framed and stress relieved bowl with high quality fabrication

prevents craking of bowl from the consistent vibratory action for long

duration

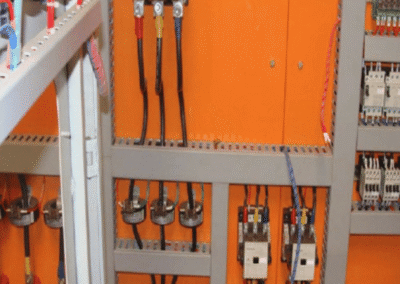

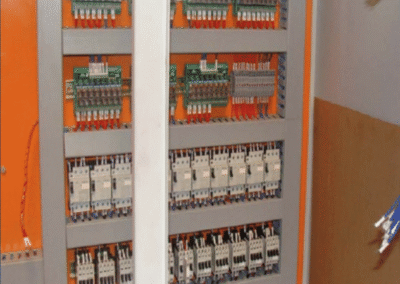

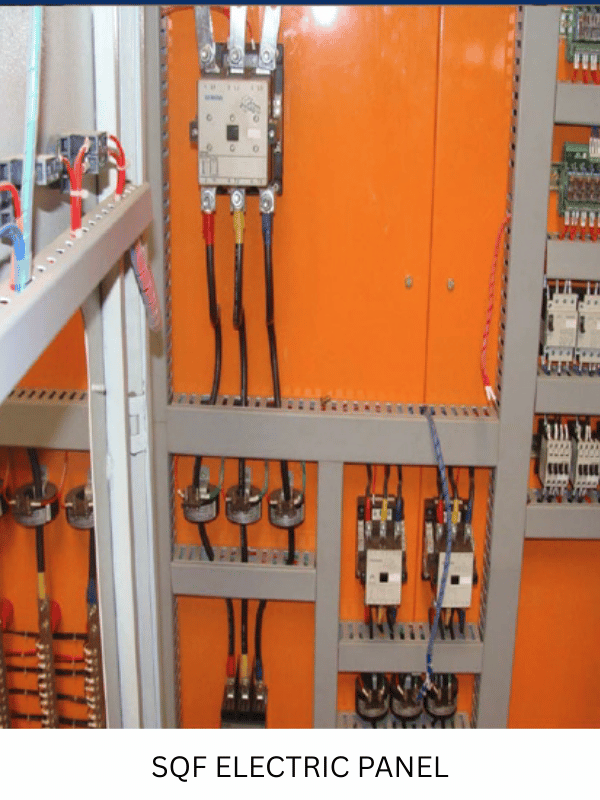

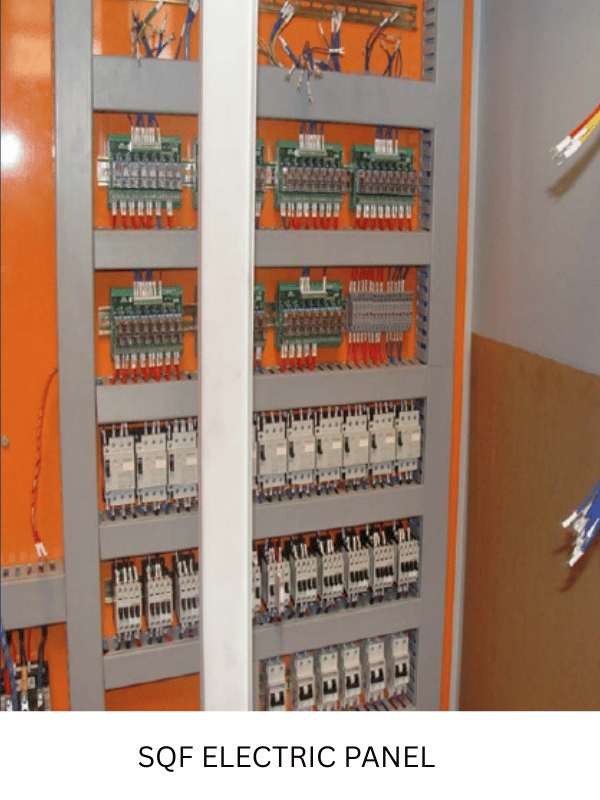

* Reputed make electrical switchgear items are provided in the control

panel

* Machine located on anti-vibration pads so that the vibration force will

not transferred to the ground

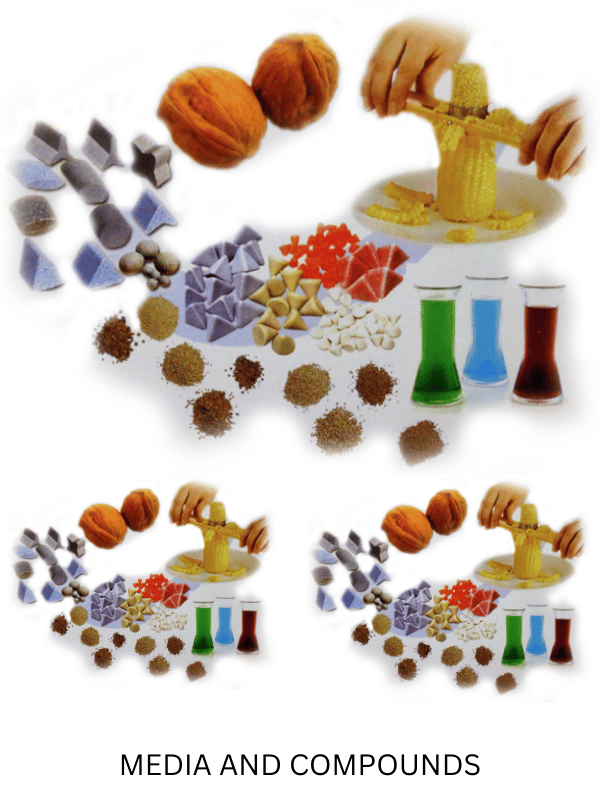

MEDIA AND COMPOUNDS

* The entire vibratory finishing process depends on the proper selection

of media and chemical compound

* There are many types of media’s are used in this process such as

Ceramic, Plastic, Porcelin, Corn-cob, steel balls and wallnut shell

* The chemical compounds also having major part in this process, for

different materials, different chemicals are used

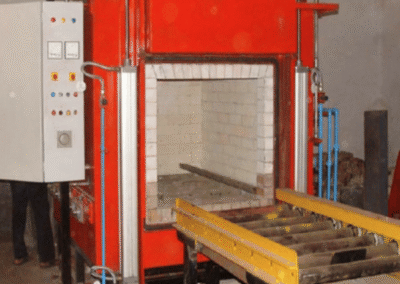

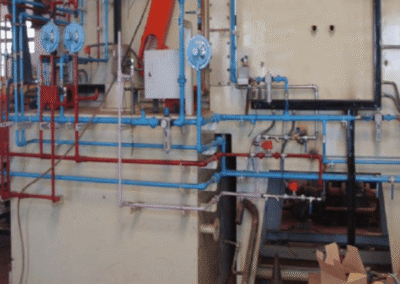

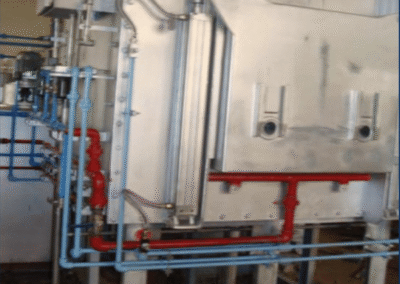

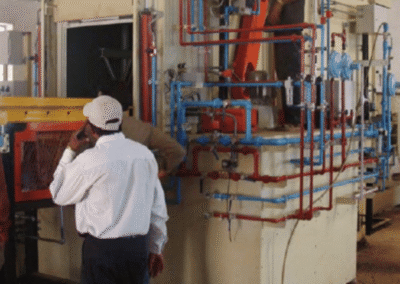

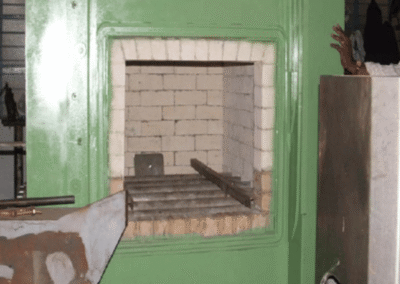

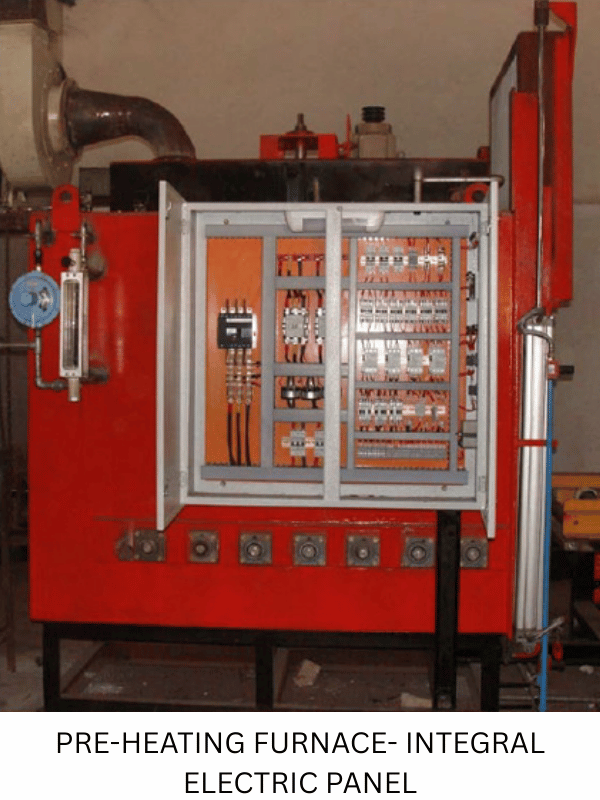

Furnace Repair & Rebuilding

Complete overhaul and restoration of existing furnace systems

- On-site inspection and assessment

- Refractory replacement and re-lining

- Heating element replacement

- Control system upgrades

- Structural repairs and modifications

- Performance testing and certification

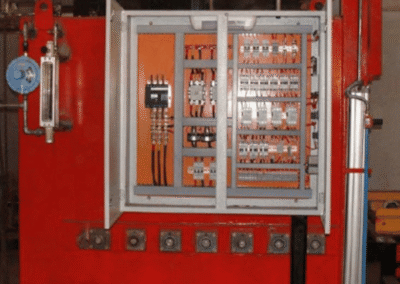

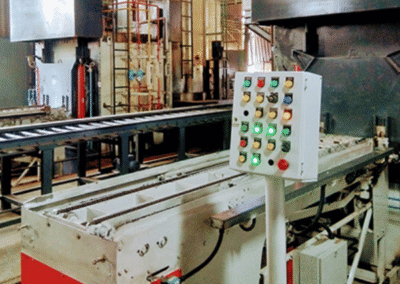

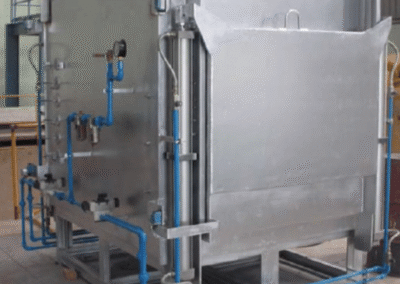

Furnace Retrofitting & Upgrades

Modernize your existing furnaces with latest technology

- PLC and SCADA system integration

- Energy efficiency improvements

- Atmosphere control system upgrades

- Safety system enhancements

- Automation and material handling

- Temperature uniformity improvements

Annual Maintenance Contracts (AMC)

Preventive maintenance programs to ensure optimal performance

- Scheduled preventive maintenance visits

- Priority breakdown support

- Genuine spare parts supply

- Performance monitoring and reporting

- Technical consultation

- Extended equipment life

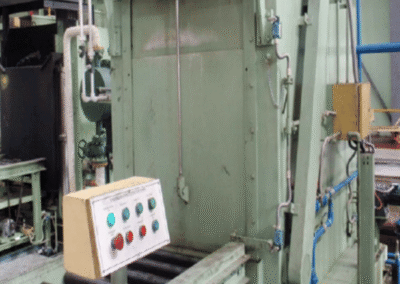

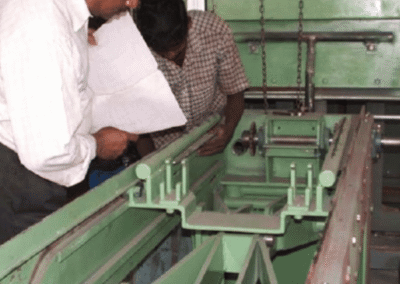

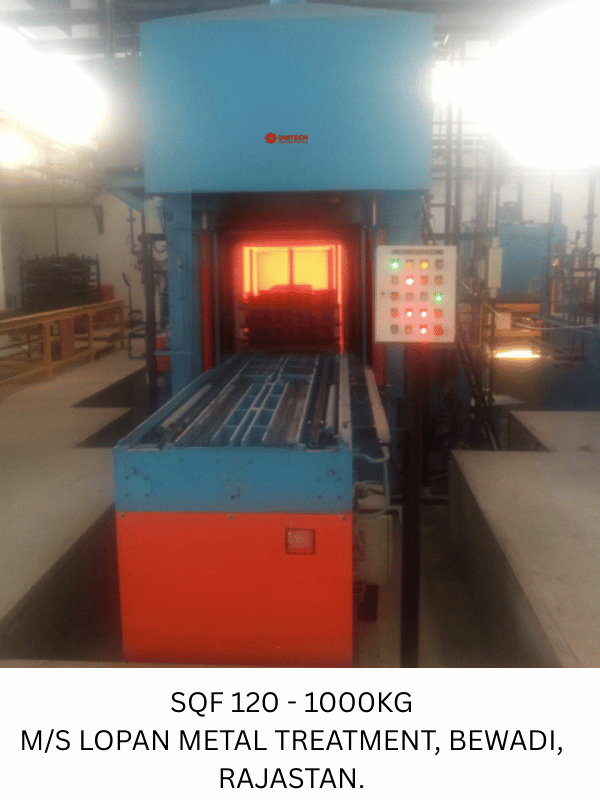

Turnkey Project Execution

Complete heat treatment facility setup from concept to commissioning

- Process engineering and layout design

- Equipment selection and procurement

- Installation and commissioning

- Operator training programs

- Process validation

- Documentation and compliance